Mast[]

Oct. 31/2010

Preliminary Mast designed, focusing on ease of manufacturing. Predicted layup is layers of unidirectional carbon followed by carbon braid for additional torsional stiffness and aesthetics.

Construction Method[]

The mast will be built around a male mandrel made of machined plastic. Acetal copolymer was priced to be cost efficient as well as having desirable characteristics (i.e. ease of machinibility and low porosity). Potential source from Professional Plastics.

3 spreaders will be built into the mast during initial construction by using separate mandrels.

Cheaper options include using wooden mandrels covered in mold release, or foam mandrels dissolved out.

Jan 25/2011

We have decided to forego building our own mast, and will purchase a filament wound foil section. Building a mast was deemed too complex, with potential for gross failure very high. The mast selected will weigh less than 600g, and will be considerably stiffer than what we could build. For simplicity, the same company will also supply the two booms, also made from filament wound carbon.

Feb 3/2011

Looking at different Carbon Mast companies that will fit our specifications. All companies that make carbon masts at some type are listed at Nautic Expo.

- Super Spars - CG190/218 or CG222/250 will work for our specifications, only problem is they are circular and not elliptical masts.

Wire Rigging:[]

We currently have ~200ft of 0.8mm 68kg downrigger wire. Need crimps and crimping tool. The shrouds will be connected to the boat using brummel hooks. These simple hooks allow quick attachment without the possibility of getting lost.

Jan 24/2011

Crimps and crimping tool have been purchased and tested on the downrigger wire. Using two crimps per eyelet gave excellent strength.

Sail Attachment[]

The mainsail can be attached to the mast in several ways:

- a luff sleeve, where the luff of the mainsail is a long tube, and slides over the mast.

- bolt rope and mast track, where the sail has a rope sewn into the luff, which mates with a track on the mast

- sail ties, where the sail is bent onto the mast by way of several (ie every few inches) bits of string

Final build and Decisions[]

1) filament wound mast from C-Tech Carbon Technologies, an elliptical profile with variable wall thickness (stiffer along major axis, fore-aft).

2) carbon battens from CT Sailbatten, tapered

3) dacron sails, dacron and doublesided tape supplied by Kingston Sail Loft. sails are bent on using sail ties. Original decision to use a luff sleeve was tried, but extremely hard to do properly, resulting in poor sail shape. Luff of jib is stiffend using nylon webbing, held on with tape. Vinyl letters attached

4) Wind sensor mount machined from plasitc, including threads, carbon-wrapped to attach to mast.

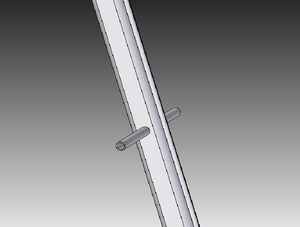

5) Bronze tube spreaders, through-mast mounted, wrapped in carbon.

Rig Tension[]

Rig tension is necessary to maintain proper mast shape. Standing rigging allows the mast to be reduced in overall size, while maintaining overall strength. However, to keep the mast in column as the wind strength increase, rig tension must also increase.

In the new rig, instead of having one turnbuckle for each shroud base, we will adjust the shrouds in pairs. This ensures equal tension on either side, reduces weight, and simplifies the rigging process. Each pair of shrouds will have a starboard and port shroud, of equal length. Adjusting the mid-point will change the rig tension.